Gravure printing technology is now considered a modern printing method applied to packaging and plastic packaging printing technologies… Gravure printing machines can be used on all film materials, composite coatings, and are supplied to you. customers with premium products.

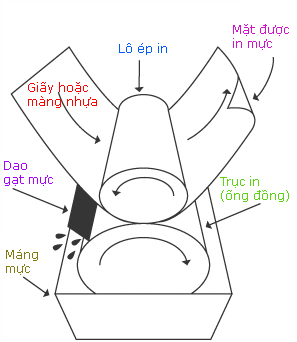

Gravure printing in principle is a concave printing method, that is, on a printing mold, images or writing (called printing elements) are engraved concavely into the metal surface. When printing, there will be 2 processes: Ink (liquid) is supplied to the surface of the printing plate, of course the ink will also overflow into the depressions of the printing element, then a device called a scraper will remove excess ink. from the surface of the printing plate, and when pressed, the ink in the depressions under the printing pressure is transferred to the surface of the material.

The ink in the non-printing element is wiped away by the ink knife, then the ink is only contained in the holes (printing element), and the ink from these holes is transferred to the surface of the printed material thanks to high printing pressure and adhesion. material. Since gravure ink has a low viscosity (about 0.1 Pa.s), there is a drying unit after each printing unit

The gravure printing mold has the form of a metal shaft, made of steel, the surface is plated with a thin layer of copper, the printing element will be engraved on the surface of this copper layer by acid or more modernly using a shaft engraving machine.

It is now possible to fabricate gravure printing molds by photochemical or electronic etching methods. Photochemical methods are based on photographic processes, physicochemical processes, mechanical processes and electrolysis.

Recoverability in gravure printing is greater, with higher accuracy than offset printing. The durability of the printing roller is large (if it is well preserved, it can be used for reprinting), the cost of the printing roller is high, so it requires a very large number of prints.

Gravure printing is applied in the printing industry of plastic film packaging, such as OMO, Viso, Bibica confectionery, or Trung Nguyen coffee… All are printed by gravure printing method.

Hotline: 0868 579 602

Hotline: 0868 579 602